How to Manufacture a "Glued & Turned" edged Rug.

| Click on images to Zoom-IN, then click the image to Return to this page. |

If you require a Rug with a finished size of say 350cm x 400cm, you need to use/cut a piece 370cm x 420cm, as the extra 20cm is Turned under & Glued (10cm turn) is required around the whole perimeter of the rug, this extra material weight also assists the rug to lay flat, or you can make a narrower turns!

All you need to start is a pair of Scissors, to make Cutting a lot easier. |

|

|

|

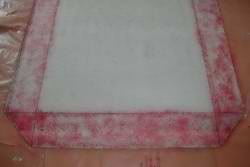

A) So, after cutting your rug 20cm over size, Turn Upside down and with a Texta draw a line 20cm in from the perimeter, remember to also draw lines across the corners and Cut off the corners prior to applying RED Contact Cement (or standard contact), the above shows this already done. We spray the contact, but you can Roll the Contact Cement on, spraying uses far less, contact cement can be thinned to make spraying easier. |

|

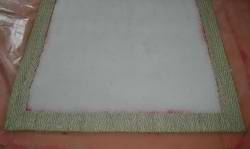

B) If you are attempt to do this for the first time, we recommend you glue one edge at a time, and either turn both ends or sides, before doing the opposite turns.

Always start each Turn, Folding from the middle of a turn NOT the end, folding from the centre stops the material creeping sideways whilst folding over. Letting the contact dry according to the glue you use, pressing the carpet to the Texta line, pressing firmly as you go, then Walk-on it, we use a 80kg steel roller to press the turn into contact cement. |

NOTE: If using common yellow contact cement, when it is applied it is difficult to see, so you can break the end off a red or blue ink biro and mix it into the contact cement, this colours the glue making it easier to see where you are applying the glue. |

|

|

|

C) Once you have glued & turned all the edges, we use a clear pellet type glue gun, instead of the PVA glue as it dries quicker, you can applying a liberal amount of PVA glue to a mitre join & let it Totally dry before moving it, glueing the corners stops them from separating over time, a cheap pellet Glue gun can be purchased from your local hardware for approx $25, the good thing with a glue gun, you can glue in bits if you make a mistake on the mitre joints, although it will be beneath the rug and not show.

We cut short fibre strands from the corner piece & glue them into the mitre join for a tidier finish. |

|

D) Whatever type of Underlay you use, first cut it in net to the turned edge or leave the underlay 2~3mm short of the outer turned edges. The above image shows Red contact cement sprayed on the back of the Rug & Underlay, again you can thin & spray or roll the contact cement on, when spraying contact cement you don't need much glue to hold the Underlay and the Turned Edges in place. Red contact cement is a special commercial heat resistant Laminex glue not commonly available. |

|

|

|

E) Carefully lay the Glued Underlay onto the Rug recessed backing, we use a Roller, you can Walk or Pressing down the underlay with a smooth block of timber, Better to let the contact totally dry before attempting to roll-up or turn over. |

|

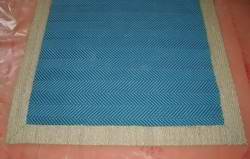

A finished Herringbone Seagrass Turned & Glued Runner. |

| Go to Job Portfolio |

|

|

|

|